Objectives

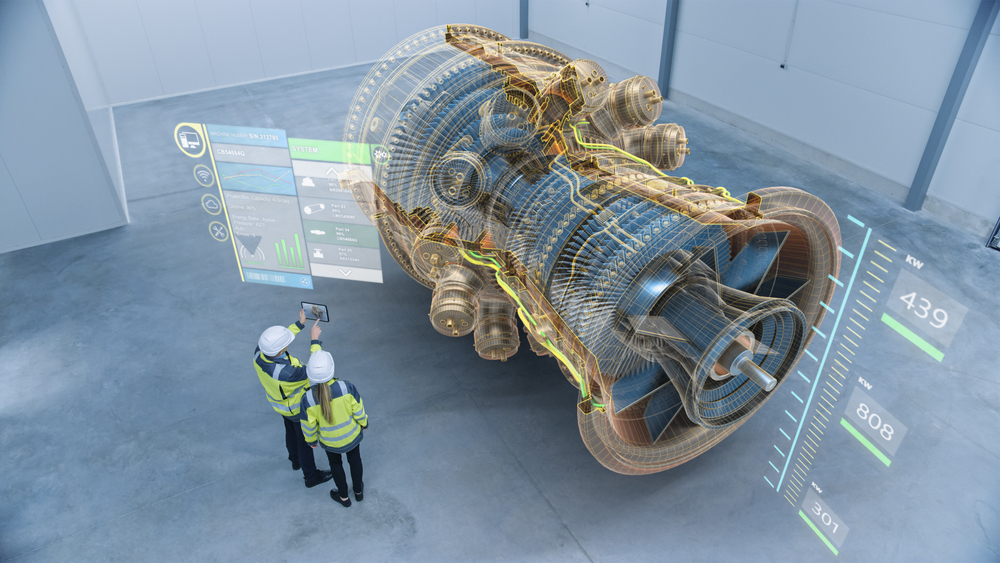

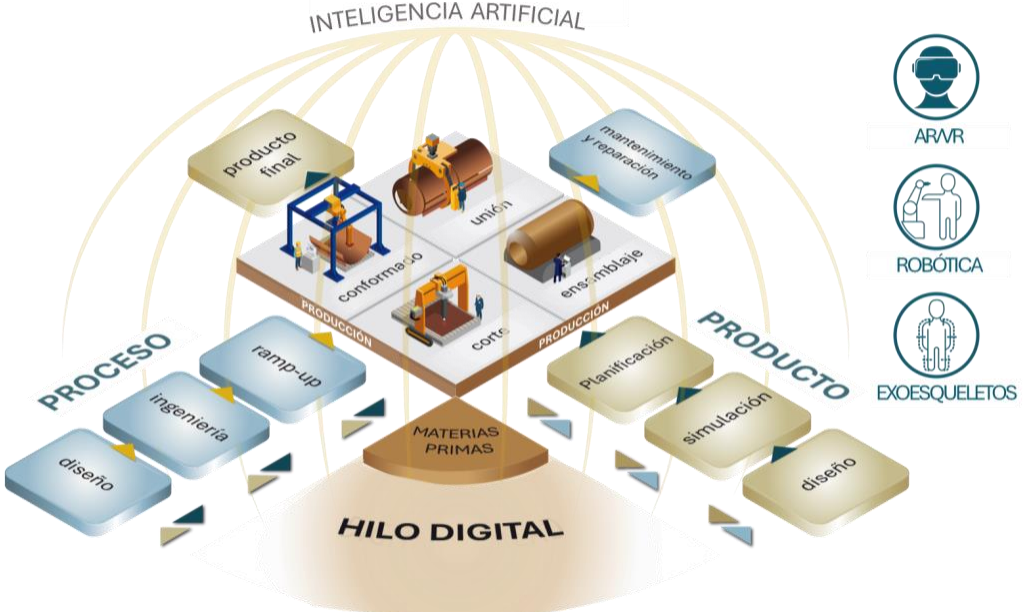

The main objective is to develop a digital manufacturing methodology that enables intelligent, and autonomous factories, recording the evolution of the product’s digital twin throughout its lifecycle. This requires monitoring and control tools based on edge IoT devices to achieve connectivity and interoperability in the supply chain. At the factory level, digital tools such as collaborative robotics, augmented reality, and exoskeletons are proposed to extend the capabilities of operators and increase efficiency and precision in the manufacturing.

NVISION role:

NVISION develops a DSS (Decision Support System) that uses Artificial Intelligence tools to analyze real-time process data. This ensures greater efficiency and control of processes, improves product quality, and enhances traceability in the supply chain.

Funding:

Funded by the Center for Technological Development and Innovation (CDTI) and the State Research Agency (AEI), as part of the State Plan for Scientific, Technical, and Innovation Research (PEICTI).